|

Electronic Services features: Electronic Services features:

Experienced & reliable company, Low cost and High quality; Experienced & reliable company, Low cost and High quality;

Multiple BGA, CGA, QFP, LPBGA, LCC, TSOP, flip-chip (all current technology). Multiple BGA, CGA, QFP, LPBGA, LCC, TSOP, flip-chip (all current technology).

ERSAscope optical inspection. ERSAscope optical inspection.

X-ray inspection. X-ray inspection.

Controlled removal/rework if ever required. Controlled removal/rework if ever required.

Re-balling of faulty or used devices. Re-balling of faulty or used devices.

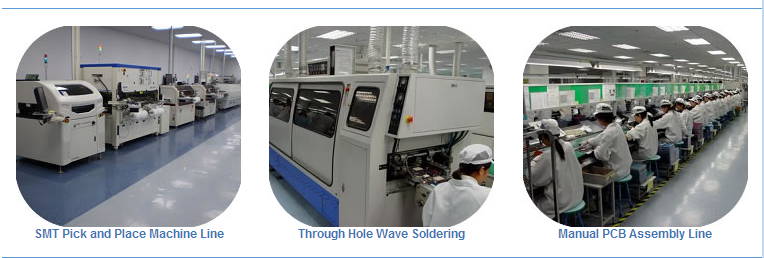

Surface Mount Electronic PCB Assembly Manufacturer Surface Mount Electronic PCB Assembly Manufacturer

The Preferred Surface Mount Technology (SMT) board is one which has Surface Mount Technology (SMT) components on one side. If all of the components are not available in Surface Mount Technology (SMT) form, Thru-hole components on the same side as Surface Mount Technology (SMT) components is a low cost solution.

SMT Plant List:

SMT Line 1

DEK 265 Infinity Screen Printer.

Nutek PCB loaders and un loaders

SMT 1.7 Forced Air Convection Reflow Oven

SMT Line 2

DEK 265 GSX Screen Printer

Philips GEM Emerald Placement Machine 0402-54mm2

ABW 1008 Forced Air Convection Reflow Oven

SMT Line 3

DEK 248 Screen Printer with DEK Align

Philips GEM Emerald Placement Machine 0402-54mm2

SMT 1.7 Forced Air Convection Reflow Oven

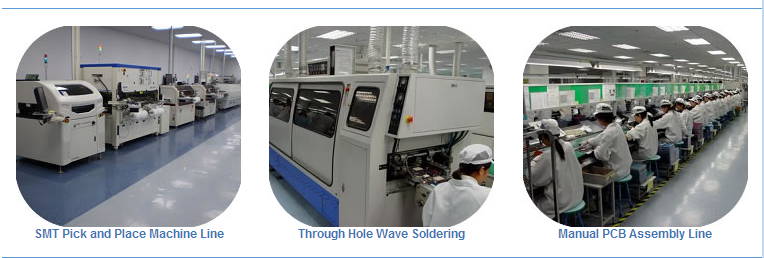

Though hole Electronic components wave soldering, wire cable hand place hand soldering Though hole Electronic components wave soldering, wire cable hand place hand soldering

Wave soldering

Wave soldering machine, RoHs compliant

Lead Free Electronic PCB Assembly Lead Free Electronic PCB Assembly

Inspection

There are a number of visual differences between leaded and un-leaded solder joints. IPC A 610 has been up issued to account for this.

One benefit we have found is that because the solder joint tends to be less shiny the capability of our AOI systems to successfully inspect solder joints is greatly improved.

Prototype Electronic PCB Assembly Prototype Electronic PCB Assembly

Offering assistance and advice in best manufacturing procedures.

Establishing a unique process for a new product.

Achieving cost reduction from an established product.

Conventional Electronic PCB Assembly Conventional Electronic PCB Assembly

70% reduction in Customer held stock/inventory.

99.6% on time delivery agains a varying demand pattern.

0.3% reject level.

Complete Electronics Product Assembly Complete Electronics Product Assembly

PCBSINO also offer facilities for "Complete" product assembly, a value adding service that is taken advantage of by an increasing number of our customers. Where production is ongoing we have set up flow lines dedicated to the assembly, testing and packaging of customers products. This gives the benefit that products can be processed quickly even in high volumes with in process inspection of each assembly operation integrated as part of the line.

Electronic board Inspection Electronic board Inspection

Automatic Optical Inspection

Electronic board BGA Inspection

Electronic PCB board BGAs are inspected both visually using an "Ersa Scope" and using an X–Ray system.

X-RAY

The 2 Axis bench top model provides an X-Ray inspection facility to supplement the ERSA cope providing a comprehensive BGA Inspection capability.

|